Industrial safety is crucial in any workplace. One key element to enhance safety is the use of Industrial Safety Floor Mats. According to a leading expert in workplace safety, Dr. Emily Larson, “Implementing quality floor mats can reduce slip and fall incidents significantly.” This highlights their importance in various environments, especially manufacturing and retail spaces.

Industrial Safety Floor Mats are designed to provide traction, comfort, and support. They are often made from materials that resist wear and can absorb impact. In busy areas, such mats can prevent accidents caused by spills, debris, or fatigue. However, not all mats are created equal. Some may fail to meet safety standards, leading to potential hazards.

Effective maintenance is also important. Mats must be cleaned regularly to ensure they don’t become slippery over time. Neglecting this can turn a safety feature into a risk. Understanding the benefits and limitations of Industrial Safety Floor Mats is essential for creating a safer workplace. A mat is only as good as the commitment to safety that surrounds it.

Industrial safety floor mats play a crucial role in optimizing workplace safety. These mats provide a non-slip surface that reduces the risk of slips and falls. Wet or greasy floors can be hazardous. Mats act as a barrier, absorbing spills and enhancing grip. They are essential in areas with heavy foot traffic, like kitchens and assembly lines.

Moreover, safety mats help minimize fatigue among workers. They offer cushioning that supports feet and joints. When employees work on hard surfaces, they often experience discomfort. This can lead to decreased productivity. Using mats can alleviate some of that discomfort, making a more pleasant working environment.

In addition, many mats are easy to clean and maintain. They can withstand harsh chemicals and conditions. However, some mats might wear out faster than expected and need replacements. Regular inspections are necessary to ensure safety remains a priority. While mats improve safety, awareness and proper usage are equally important. Only with attention to detail can workplaces be truly safe.

In high-risk work environments, safety mats play a crucial role in reducing accidents. These mats provide excellent traction, preventing slips and falls on wet or greasy surfaces. Their textured surfaces create a secure footing, which is vital in factories or kitchens. Workers can feel more confident in their movements.

However, if mats are not regularly cleaned, they can become slippery over time.

Another benefit is cushioning. Industrial safety mats offer a softer surface that eases the strain on workers' legs and feet. This is especially important for those who stand for long periods. Fatigue can lead to decreased focus and increased risk of accidents. On the flip side, improper mat placement can create tripping hazards. The arrangement needs regular assessment.

Moreover, these mats can absorb noise. In busy and noisy environments, reducing sound levels can improve concentration. Nevertheless, some mats may wear out faster, losing their effectiveness. Employers must choose appropriate mats for their specific settings. Regular inspections and timely replacements are key to maintaining safety.

Comfortable flooring can greatly impact employee well-being. Industrial safety floor mats are essential in enhancing comfort. They reduce fatigue, especially in workplaces where employees stand for long periods. Studies show that anti-fatigue mats can increase productivity by up to 20%.

Implementing these mats can also lead to fewer workplace injuries. A report from the National Safety Council indicates that slip and fall accidents account for about 25% of all workplace injuries. Proper floor mats can mitigate this risk, creating a safer environment.

Tips to consider:

- Choose mats that provide adequate cushioning for maximum comfort.

- Look for mats with slip-resistant surfaces to enhance safety.

- Ensure mats are regularly cleaned to maintain hygiene and effectiveness.

By incorporating proper floor mats, businesses can prioritize employee health and safety. It's a small investment for a significant return. However, not all mats are created equal; some may wear down quickly or fail to provide the necessary support. Regular assessments of mat conditions can ensure employees remain comfortable and productive.

In workplaces, slips, trips, and falls are common hazards. According to the National Safety Council, these incidents account for nearly 25% of all workplace injuries. Industrial safety floor mats play a crucial role in minimizing these risks. Their textured surfaces provide traction, reducing the likelihood of slips. Utilizing mats in high-risk areas like kitchens or warehouses can make a significant difference.

Implementing safety mats is not just about compliance. The return on investment is notable. The costs associated with workplace injuries can be substantial. Reports indicate that for every dollar spent on safety measures, businesses can save up to $4 in injury-related costs. However, some may overlook the need for regular maintenance. Worn-out mats may lose their effectiveness. This negligence can lead to accidents that could have been easily prevented.

Workplaces should also consider the placement of mats strategically. Areas prone to spills or where employees frequently walk need careful attention. Yet, some facilities may fail to assess the true nature of their risks. Ignoring these factors can result in unnecessary injuries. Regular training and awareness programs are essential for maximizing the benefits of safety mats. They ensure that employees recognize the importance of their environment.

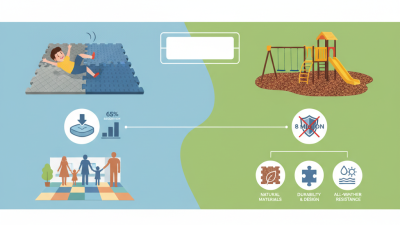

When selecting safety mats for your workplace, consider the specific needs of your environment. Different types of mats serve various purposes, from providing comfort during long standing hours to preventing slips and falls. Antifatigue mats are ideal for those who stand at work, promoting better posture and reducing fatigue. On the other hand, anti-slip mats offer grip in potentially hazardous areas like kitchens or industrial zones.

Think about the material as well. Rubber mats are durable and weather-resistant, making them suitable for outdoor areas. Foam mats provide cushioning indoors but may not be suitable for wet conditions. Also, remember to consider the thickness of the mats. Thicker mats can offer more comfort but might be more difficult to clean. The colors and patterns can also impact safety; bright colors can enhance visibility.

It’s crucial to evaluate your safety conditions. Poorly chosen mats can lead to accidents or discomfort. Regularly inspect and replace worn-out mats as necessary; neglect can diminish their protective benefits. Observing how these elements interact in your space can guide better choices, creating a safer workplace for all.