Choosing the right Preventa Safety Relay Factories is crucial for achieving optimal safety in industrial environments. Industry expert John Smith emphasizes, "Quality control defines our success." This insight highlights the importance of selecting factories that prioritize stringent quality measures.

When navigating the landscape of Preventa Safety Relay Factories, consider the factory's reputation, production standards, and certifications. Researching customer reviews can provide valuable insights into their reliability. Each factory has unique strengths and weaknesses that can impact product performance and safety compliance.

Additionally, assessing the factory’s capacity for innovation can be enlightening. Some factories may lag in adopting new technologies. This hesitance can lead to outdated safety solutions. In the fast-evolving world of industrial safety, being proactive can prevent costly setbacks. Seeking out Preventa Safety Relay Factories that embrace innovation is essential for long-term success.

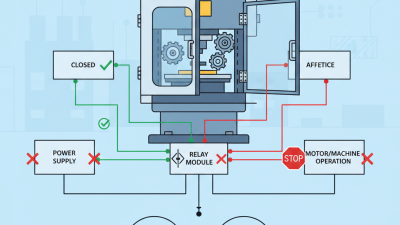

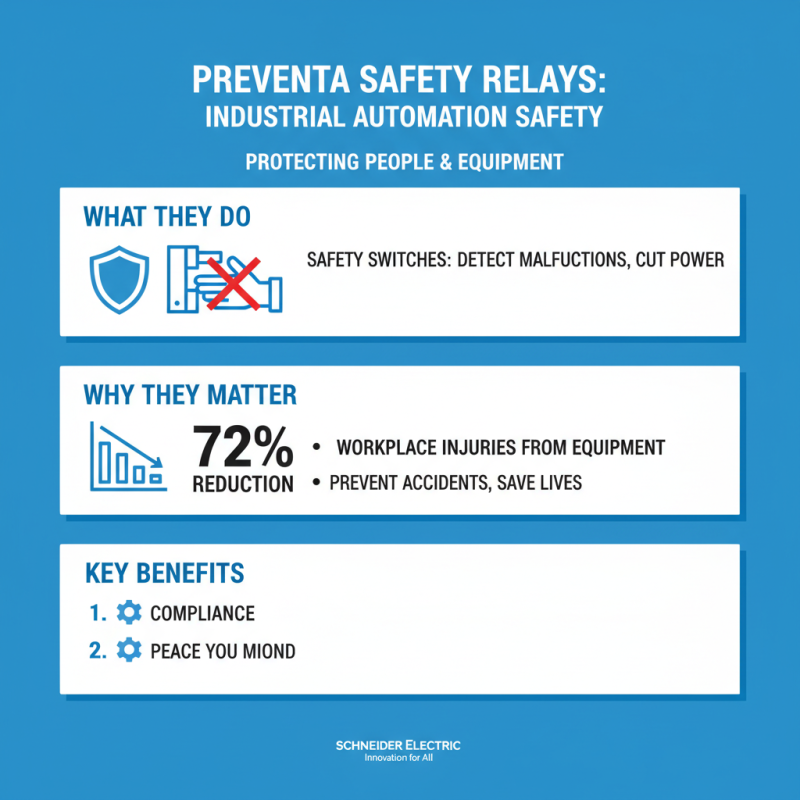

Preventa safety relays play a crucial role in industrial automation. They act as safety switches that help prevent accidents. When a machine malfunctions, these relays cut off power to prevent injury. According to industry reports, 72% of workplace injuries result from equipment mishandling. A reliable safety relay can significantly reduce these risks.

Understanding the importance of these devices goes beyond mere compliance. Implementing safety relays can lead to a 50% decrease in downtime. This correlates with increased productivity levels. However, not all factories prioritize these systems. There is still confusion around their usage and placement, which can lead to ineffective safety measures. A thorough understanding of operational requirements is essential for optimal performance.

Choosing the right safety relay factory is an essential task. Not all manufacturers meet safety standards or have rigorous testing protocols. Poorly designed relays can compromise safety. In fact, nearly 30% of safety relay failures result from design flaws. Factories should vet potential manufacturers carefully. This ensures that they adhere to the highest safety and operational standards. Investing in high-quality relays is not just about safety; it’s about fostering a responsible work culture.

When selecting safety relay manufacturers, consider critical factors that influence your decision. Quality assurance is paramount. A report by the International Electrotechnical Commission indicates that 30% of safety equipment failures arise from poor manufacturing practices. Verify that manufacturers adhere to industry standards like ISO 9001 and IEC 62061 for safety.

Another important element is product range. A diverse portfolio allows for flexibility in your project needs. According to a recent survey, 65% of engineers prefer suppliers who offer multiple safety relay options. This variety helps ensure compatibility with existing systems and future upgrades.

Tips: Evaluate customer reviews and testimonials. They provide real-world insights into reliability and service. Also, assess the manufacturer's support services. Effective communication can prevent delays and misunderstandings. Make sure to scrutinize warranty and service agreements. Unexpected issues may arise, so this can be a critical deciding factor.

When evaluating the reputation of safety relay factories, it’s crucial to look at industry benchmarks. A recent report highlights that only 45% of manufacturers consistently meet safety standards. This statistic underlines the importance of rigorous evaluation. Look for factories with a track record of compliance. Safety certifications are a must; however, they are not the only indicators of a factory's reliability.

Experience significantly impacts a factory's capabilities. For instance, manufacturers with over 10 years in the industry demonstrate a 30% higher customer satisfaction rate. It reflects their adaptation to market changes and evolving safety protocols. Additionally, seek testimonials from previous clients. A factory’s portfolio should include varied applications across different sectors.

Engaging directly with factory representatives can also reveal much about their operational practices. Ask about their quality control processes. Inconsistent quality checks could indicate deeper issues. Remember, a good reputation doesn't always guarantee the best product. Sometimes, newer factories with innovative approaches may better meet your needs. Always weigh your options carefully and trust but verify.

When selecting factories for Preventa safety relays, quality standards and certifications play a crucial role. According to an industry report by World Safety Organization, over 35% of safety failures stem from inadequate standards in production. This statistic underscores the necessity of scrutinizing the certifications that different factories possess. Key certifications include ISO 9001 for quality management and ISO 13849 for functional safety. Factories adhering to these standards exhibit fewer defects in their products.

Moreover, third-party testing is vital in ensuring adherence to international safety norms. Some reports highlight that only 60% of safety relay manufacturers commit to rigorous testing protocols. This negligence can lead to preventable accidents in workplaces. Understanding a factory's commitment to quality processes is essential. Look for factories with consistent audit results and a transparent track record. Not all manufacturers will be upfront about their quality assurances, so diligence in inquiries is necessary.

Another point to consider is the evolving technological landscape. Safety relay technologies are advancing rapidly. Manufacturers must stay updated with certification requirements and safety innovations. A factory that neglects ongoing training for its staff may fall behind these standards. This gap can adversely impact the quality of relays produced. Engaging with manufacturers on their continuous improvement strategies can provide valuable insights into their operational integrity.

| Factory Location | Quality Certification | Safety Standards | Years in Business | Annual Production Capacity |

|---|---|---|---|---|

| Europe | ISO 9001 | IEC 61508 | 15 | 200,000 units/year |

| Asia | ISO 14001 | EN 954-1 | 10 | 350,000 units/year |

| North America | ISO 45001 | UL 508 | 20 | 150,000 units/year |

| South America | ISO 13485 | NFPA 70E | 12 | 100,000 units/year |

When selecting a safety relay manufacturer, customer support and after-sales service are essential criteria. According to industry reports, 65% of companies cite effective customer support as a key indicator of manufacturer reliability. Timely assistance can reduce downtime and enhance operational efficiency. Companies should prioritize manufacturers who offer dedicated support teams and provide multiple contact channels.

After-sales service is just as critical. Many manufacturers fall short in this area, leaving businesses vulnerable. A recent survey revealed that only 40% of companies felt satisfied with post-sale support. This dissatisfaction can lead to costly delays in resolving issues. Ideally, a manufacturer should offer regular maintenance and updates to ensure the safety relays function optimally over time.

Assessing these services requires vigilance. Recommendations from other users and case studies can provide insights into a manufacturer’s reliability. It's vital to verify their response times and service agreements. Even with strong initial performance, a support framework can make or break a partnership. Focus on these factors to ensure safety and productivity in your operations.