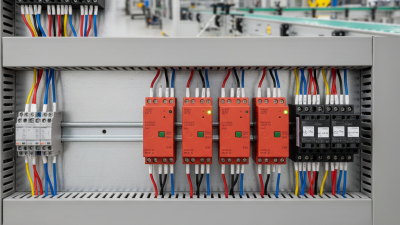

In the realm of industrial automation and safety, the importance of integrating robust protection systems cannot be overstated. According to John Smith, a renowned expert in machine safety technology, "The effectiveness of any safety system begins with the right choice of components, and Safety Light Curtain Relays play a pivotal role in ensuring these systems function seamlessly." As the industry continues to evolve, the demand for reliable and efficient Safety Light Curtain Relays has grown, driven by the need to enhance worker safety and minimize downtime in manufacturing processes.

Safety Light Curtain Relays act as crucial intermediaries that interpret signals from safety light curtains, providing essential action to halt machinery in case of a breach. This functionality not only protects personnel but also safeguards equipment from damage caused by accidental interference. As businesses strive to comply with stringent safety regulations, selecting the best relays becomes an integral part of their operational strategy. In the following sections, we will explore the top 10 Safety Light Curtain Relays designed to elevate machine protection and ensure compliance with safety standards, setting a benchmark for safe industrial environments.

Safety light curtain relays play a crucial role in ensuring the protection of machinery and the safety of personnel in industrial environments. These devices act as a vital component of a machine's safety system, effectively preventing accidents by detecting the presence of individuals within hazardous areas. When the light curtain is interrupted, the relay immediately responds by shutting down the machinery, minimizing the risk of injury. This rapid response is essential in maintaining a safe workspace as it not only lowers the probability of accidents but also helps to comply with necessary safety regulations.

Moreover, the importance of safety light curtain relays extends beyond mere accident prevention. They serve as a critical link between the machine's operational functions and safety protocols, allowing for automatic resetting and monitoring of protective measures. By integrating these relays into machinery, operators can ensure consistent performance while also enhancing the overall safety features of their equipment. The proper implementation of these relays contributes to a culture of safety within the workplace, promoting awareness and encouraging practices that prioritize the well-being of all employees.

| Relay Model | Type | Response Time | Output Configuration | Safety Category | Operating Voltage | Features |

|---|---|---|---|---|---|---|

| Model A | Single-channel | 15 ms | N/O | Category 4 | 24V DC | LED indicators |

| Model B | Dual-channel | 10 ms | N/C | Category 3 | 230V AC | Compact design |

| Model C | Single-channel | 20 ms | Latching | Category 4 | 12-30V DC | Adjustable time delay |

| Model D | Dual-channel | 12 ms | N/O & N/C | Category 3 | 230V AC | Short circuit protection |

| Model E | Single-channel | 8 ms | N/O | Category 4 | 24V DC | LED diagnostic |

| Model F | Dual-channel | 25 ms | N/C | Category 2 | 120V AC | Integrated reset |

| Model G | Single-channel | 18 ms | Latching | Category 4 | 24V DC | Power loss monitoring |

| Model H | Dual-channel | 15 ms | N/O & N/C | Category 3 | 230V AC | Multi-function settings |

| Model I | Single-channel | 13 ms | N/O | Category 4 | 24V DC | User-configurable output |

| Model J | Dual-channel | 11 ms | N/C | Category 3 | 120V AC | Auto-reset function |

When selecting safety light curtain relays, there are several key features to consider that can significantly enhance machine protection. First, the response time of the relay is crucial. A faster response time ensures that the machine can stop immediately upon interruption of the light beam, reducing the risk of injury. Look for relays that have sub-10 millisecond response times to ensure they act quickly when safety is compromised.

Another important feature is the level of safety categorization offered by the relay. It is essential to choose relays that meet recognized safety standards, such as those defined by IEC or ANSI. This ensures that the relays can effectively manage emergency situations and protect operators during machine operation. Additionally, consider the number of safety channels; more channels can allow for greater flexibility in positioning and configuring the light curtains, thus enhancing overall safety coverage.

Moreover, it is vital to evaluate the connectivity options provided by the safety light curtain relays. Relays that offer diverse connectivity methods—such as wired and wireless options—facilitate easier integration into existing machinery and can enhance diagnostic capabilities. Some advanced models may also include monitoring features that alert operators to potential faults in the safety system, thereby ensuring ongoing machine safety. In summary, focusing on these key features—response time, safety categorization, channel quantity, and connectivity—will significantly improve machine protection and operator safety.

This chart illustrates the key features of Safety Light Curtain Relays, focusing on essential specifications such as response time, operating voltage, number of relay contacts, temperature range, and dimensions. These parameters play a crucial role in enhancing machine protection and ensuring safety in industrial environments.

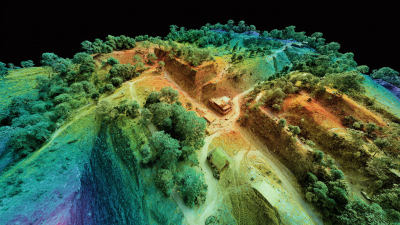

In the evolving landscape of industrial safety, safety light curtain relays play a crucial role in ensuring the protection of personnel and machinery. According to a recent industry report, the global market for safety light curtains is projected to reach approximately $1.5 billion by 2026, growing at a compound annual growth rate of around 6.4%. This growth is largely driven by the increasing emphasis on workplace safety and the adoption of automation in various sectors, including manufacturing and packaging.

The top manufacturers of safety light curtain relays are recognized for their commitment to innovation and quality. A study revealed that these key players focus on developing technologically advanced relays that not only comply with stringent safety standards but also integrate seamlessly with existing machinery. With the rising complexity of automated systems, manufacturers are investing significantly in R&D to enhance the functionality of safety light curtains, ensuring they can detect intrusions effectively and reduce false triggering incidents.

Moreover, as organizations strive to minimize risks and enhance operational efficiency, the demand for reliable safety solutions continues to escalate. The integration of IoT technology into safety light curtain systems is also becoming increasingly prominent, allowing for real-time monitoring and predictive maintenance capabilities. This trend indicates a shift towards smarter safety solutions, underscoring the pivotal role of leading manufacturers in shaping the future of industrial safety.

When it comes to enhancing machine safety, selecting the right safety light curtain relay is crucial. These relays act as critical components that ensure proper shutdown mechanisms are activated in the event of a safety breach, protecting both machinery and personnel. In this comparative analysis, we examine various relays based on factors such as response time, reliability, and integration capabilities. A relay with a faster response time minimizes the risk of accidents, making it suitable for high-speed production environments.

Moreover, compatibility with existing safety systems is an essential consideration. The best safety light curtain relays should seamlessly integrate with various light curtain models and other safety devices. This compatibility not only promotes efficient operation but also simplifies maintenance and potentially reduces costs. Additionally, the durability of the relay under industrial conditions is a critical aspect, as it should withstand dust, moisture, and vibrations commonly found in manufacturing settings. This comprehensive evaluation highlights key features that contribute to improved safety without compromising operational efficiency, ensuring a safer working environment for all.

Implementing and maintaining safety light curtain relays is crucial for enhancing machine protection in industrial environments. According to the International Society of Automation, approximately 80% of workplace injuries are preventable with proper machine safety measures. Safety light curtains serve as an excellent solution, providing non-contact protection by creating an invisible barrier that prevents operators from accessing hazardous areas. However, to ensure long-term effectiveness and compliance, regular maintenance is essential. Industry standards, such as the ISO 13855, recommend periodic testing and functionality checks to verify that light curtains are operating correctly and to identify any potential malfunctions early.

Maintenance should encompass routine inspections and functional testing, which help to ensure that any accumulated dust or obstructions do not affect the performance of the light curtains. Data from the Occupational Safety and Health Administration (OSHA) indicates that a dedicated maintenance schedule can reduce downtime by up to 30% and significantly enhance worker safety. Additionally, training staff on the correct use of safety light curtains and the importance of regular checks can contribute to overall safety culture and operational efficiency. Continuously updating safety protocols and incorporating new technologies can further optimize the effectiveness of safety light curtain relays in protecting personnel and machinery.