In the world of industrial automation, ensuring operational safety is of paramount importance. As manufacturing processes grow increasingly complex, the demand for reliable safety systems becomes more critical. Among these systems, Safety Relay AB stands out as a fundamental component designed to prevent accidents and protect both personnel and equipment. This article delves into the top 10 Safety Relay AB solutions, showcasing their unique features and capabilities that contribute to enhanced operational safety.

Safety Relay AB solutions play a vital role in mitigating risks associated with machine operations. By analyzing their functionalities and advantages, we can better understand how they bolster safety measures in various industrial settings. The innovations in Safety Relay AB technology not only comply with safety standards but also offer flexibility and efficiency to meet the specific needs of diverse manufacturing environments. Join us as we explore these top solutions and their impact on creating safer workplaces.

Safety relays play a critical role in ensuring operational safety across various industries, particularly in environments that demand stringent compliance with safety standards. Understanding safety relay standards is essential for organizations looking to implement effective safety solutions. According to a report by the International Electrotechnical Commission (IEC), the IEC 61508 standard is fundamental, emphasizing functional safety in electrical, electronic, and programmable electronic systems. This standard establishes a framework for assessing safety-related systems and ensuring they meet rigorous performance requirements, thus mitigating risks and enhancing operational safety.

Another significant standard is ISO 13849, which relates to the safety of machinery. This standard provides guidance on the design and integration of safety-related parts of control systems, ensuring that safety functions are achieved through reliable components. A study by TÜV Rheinland indicates that adherence to these standards can reduce workplace accidents by up to 40%, showcasing their pivotal role in fostering safer work environments. Understanding these certifications not only aids compliance but also elevates stakeholder confidence in the safety measures implemented by an organization, driving overall productivity and operational integrity.

Safety relays play a crucial role in enhancing operational safety within automation systems. Designed to monitor safety functions, these relays ensure that machines operate within defined safety parameters, thus minimizing the risk of accidents. Key features of safety relays include dual-channel inputs, fault diagnostics, and emergency stop circuits. These elements work together to create a fail-safe environment, ensuring that if one channel fails, the system can still maintain its safety integrity through redundancy.

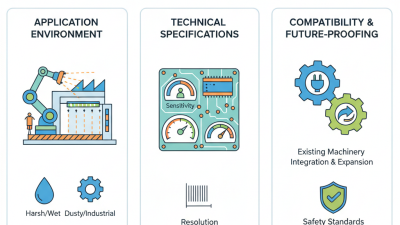

Tips for selecting an appropriate safety relay include assessing the specific safety requirements of your operation and considering the compatibility with existing machinery. It is essential to choose relays that provide clear diagnostic information, as this can significantly reduce downtime during maintenance. Additionally, always opt for relays that conform to international safety standards to ensure compliance and reliability.

Another critical feature to look for in safety relays is the ability to integrate with various types of sensors and actuators. This versatility enhances operational efficiency while maintaining safety. Training personnel on the functionality and importance of safety relays is equally vital, as it ensures that everyone involved is aware of best practices and potential hazards, reinforcing the overall safety culture within the workplace.

The implementation of safety relays has become a critical aspect of enhancing operational safety across various industries. Recent industry reports indicate that nearly 70% of manufacturing accidents can be prevented with effective safety mechanisms in place. A case study from the automotive sector demonstrated that integrating safety relays reduced downtime by 30% and significantly decreased the risk of operator injury. This implementation not only protected the workforce but also improved production efficiency, showcasing the dual benefit of prioritizing safety.

In the food processing industry, safety relays have been linked to a 40% reduction in safety incidents over a two-year period. A leading processor reported that the deployment of these safety devices led to a more robust hazard identification process, allowing for quicker response times to potential safety breaches. The consistent functionality of safety relays ensures that emergency stop mechanisms are reliable, contributing to a safer work environment. The direct correlation between safety investments and operational performance highlights the necessity for industries to adopt advanced safety relay solutions as part of their safety protocols.

This chart illustrates the percentage improvement in operational safety achieved through the implementation of safety relay solutions across various industries. Each bar represents a different sector, showcasing the effectiveness of these safety systems in enhancing workplace safety.

When evaluating the efficiency of safety relay solutions, performance metrics play a critical role in identifying the best options to enhance operational safety. Key metrics often include response time, reliability, and failure rates. A swift response time is essential; in the event of an emergency, every millisecond counts. Metrics that measure how quickly a safety relay activates or deactivates input signals provide insights into its effectiveness in preventing accidents. Additionally, reliability is assessed through rigorous testing under various conditions, ensuring the system can maintain performance over prolonged use without failure.

Another significant performance metric is the mean time between failures (MTBF), which indicates the average time expected between failures of a safety relay. A higher MTBF suggests that a safety relay can operate longer without interruption, ultimately contributing to a safer working environment. Furthermore, ease of integration with existing systems and the ability to meet specific safety standards are essential considerations. The combination of these metrics allows organizations to make informed decisions when selecting safety relay solutions, ensuring they choose products that not only comply with regulatory requirements but also optimize operational safety effectively.

The future of operational safety is being notably shaped by innovations in safety relay technology. As industries increasingly prioritize safe and efficient operations, advancements in safety relays have emerged to address new challenges. Modern safety relays are integrating smart features such as real-time monitoring and diagnostics, which enable operators to preemptively identify potential issues. This proactive approach not only enhances safety but also minimizes downtime by facilitating timely interventions.

Moreover, the use of IoT and AI technologies in safety relays is revolutionizing operational practices. With enhanced connectivity, safety relays can communicate across various systems, providing a comprehensive overview of safety parameters and potential risks. This interconnectedness allows for sophisticated risk analysis and decision-making processes, driving organizations toward a more integrated safety culture.

As organizations embrace these innovations, the shift towards more intelligent and adaptable safety solutions is evident, reflecting a commitment to ongoing improvement in workplace safety standards.