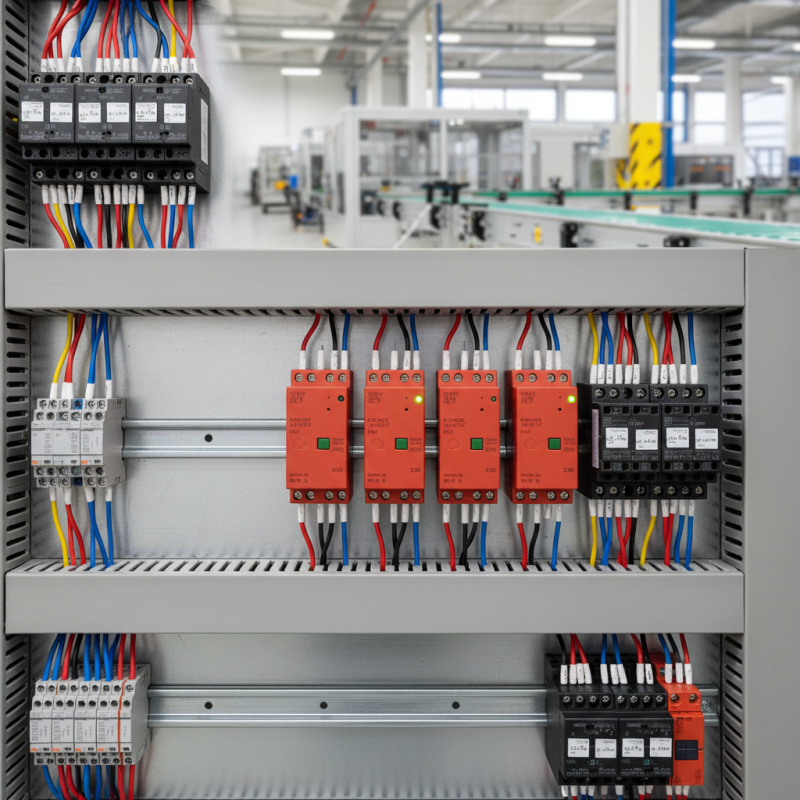

In today's rapidly advancing industrial landscape, the safety and efficiency of automation systems are more critical than ever. One of the key components that can enhance the reliability of such systems is the 24v Safety Relay. This device plays a vital role in safeguarding machinery and personnel by ensuring that automated processes operate safely and effectively. With the increasing complexity of automation tasks, the need for robust safety solutions has become paramount, leading to a surge in the adoption of 24v Safety Relays across various industries.

The benefits of integrating a 24v Safety Relay into automation systems are manifold. Firstly, these relays provide reliable isolation of control circuits, which helps prevent accidental activation of machinery. Additionally, they offer expedited response times in emergency situations, ensuring that energy supplies can be cut off almost instantaneously. Moreover, the compact design of 24v Safety Relays makes them easy to implement in existing systems without requiring significant modifications, promoting seamless integration into diverse automation setups.

As we delve deeper into the top ten benefits of utilizing a 24v Safety Relay, it becomes evident that this technology not only enhances safety but also boosts operational efficiency, ultimately leading to improved productivity in various applications. Embracing the use of 24v Safety Relays is a strategic move for organizations looking to bolster their automated processes while prioritizing safety and compliance.

The integration of a 24v safety relay into automation systems significantly enhances safety features, providing peace of mind for operators and reducing the risk of accidents. With a robust safety mechanism, these relays ensure that equipment operates within safe parameters, effectively monitoring critical processes. In environments where heavy machinery and automated systems are present, the ability to swiftly detect faults and initiate safety protocols is paramount. This proactive approach minimizes downtime and potential hazards, making a remarkable difference in operational efficiency.

Tips: When selecting a safety relay, ensure compatibility with your existing automation equipment to maximize safety features. Regular maintenance and testing of the relay can further enhance its reliability and performance, keeping your systems safe and operational.

Moreover, implementing a 24v safety relay not only protects personnel but also safeguards valuable machinery from damage due to malfunctions. These devices can facilitate emergency stops and provide redundancy, ensuring that should one component fail, the entire system does not become compromised. Emphasizing a culture of safety by utilizing advanced technology like safety relays fosters a positive work environment and reinforces the commitment to operational safety.

Tips: Conduct training sessions for your team to familiarize them with the operation and functionalities of safety relays, which will empower them to respond effectively in emergencies. Regularly update safety protocols to align with advancements in safety relay technology.

The cost efficiency of using 24v safety relays in automation operations is significant, providing a powerful solution for enhancing safety without burdening the budget. By integrating 24v safety relays, businesses can streamline their processes while minimizing downtime and maintenance costs. These relays act as a protective measure in various automation systems, ensuring that any fault conditions can be rapidly detected and remedied. This immediate response capability reduces the likelihood of extensive damage to equipment, which can save substantial repair costs in the long run.

Furthermore, the initial investment in 24v safety relays often pays off quickly through improved system reliability and reduced operational risks. By preventing potential hazards, companies not only enhance worker safety but also mitigate the financial implications associated with workplace incidents. Additionally, 24v safety relays are typically designed for easy integration into existing systems, meaning that businesses can implement them without a complete overhaul of their infrastructure, thus preserving both time and resources. Overall, the adoption of these safety devices leads to a compelling return on investment while ensuring compliance with safety regulations in automation environments.

In the realm of automation, the use of a 24v safety relay significantly enhances the reliability and performance of processes. These relays are instrumental in ensuring the safe operation of machinery and systems, providing a critical layer of protection against failures. By integrating a 24v safety relay, you can expect improved response times within automation systems, as these devices are designed to operate swiftly and efficiently, minimizing downtime and potential hazards.

Tips: When implementing a 24v safety relay, ensure that you carefully assess the layout of your automation setup. Proper placement of the relay can drastically improve its efficacy, leading to optimized performance. Additionally, regular maintenance checks on the relay can help identify issues before they escalate, further safeguarding the automation process.

Moreover, a 24v safety relay contributes to compliance with safety regulations, which are vital in many industrial environments. By fulfilling these standards, organizations can avoid costly interruptions while fostering a culture of safety. With enhanced reliability, you can trust that your automation processes will run smoothly, allowing you to focus on greater productivity and innovation within your operations.

Tips: Always keep your safety protocols updated and train your team on using safety relays effectively. This proactive approach not only boosts performance but also empowers your workforce to operate safely and efficiently.

One of the significant advantages of utilizing a 24v safety relay in automation systems is the simplification it brings to troubleshooting and maintenance. According to a report by the International Society of Automation, about 60% of system downtime can be attributed to electrical failures, many of which are preventable with effective relay systems. Safety relays play a crucial role in ensuring that only essential components remain powered during fault conditions, allowing technicians to diagnose issues without disrupting the entire system. The use of safety relays helps streamline the identification of problems, ultimately reducing downtime and operational costs.

Maintenance becomes less complex with the implementation of safety relays, as these devices often feature built-in diagnostic capabilities. By monitoring safety functions in real time, these relays provide clear indicators of system status, which can significantly reduce the time spent on routine check-ups. A study from the Automation Research Institute highlighted that facilities implementing safety relays experienced a 30% decrease in maintenance time due to these enhanced diagnostics, allowing maintenance teams to focus on proactive measures rather than reactive fixes. The improved clarity in system status alerts operators promptly, facilitating efficient responses to potential issues, thereby safeguarding both personnel and equipment.

The adaptability of 24v safety relays makes them an essential component in various industrial applications. These relays are designed to handle diverse environments and conditions, effectively enhancing safety protocols across manufacturing, automation, and process control sectors. Whether it's a small-scale assembly line or a large industrial plant, 24v safety relays provide reliability and flexibility, allowing businesses to tailor safety measures to meet specific operational requirements.

When implementing 24v safety relays, it is crucial to ensure compatibility with existing systems. Many industries benefit from integrating these relays into machinery that requires fail-safe operations, including robotics, conveyor systems, and emergency stop mechanisms. The ability to customize these relays for multiple configurations promotes efficient use of space and resources while maintaining high safety standards.

Tips: Always conduct a comprehensive risk assessment before selecting safety relays for your systems. It's essential to consider the unique demands of your application, such as load requirements and environmental factors. Additionally, regular maintenance checks can significantly extend the lifespan of your safety relays, ensuring they function optimally in safeguarding your operations.

This chart illustrates the top benefits of using a 24v safety relay in various industrial applications, highlighting aspects such as safety, adaptability, and ease of integration.