Safety grating light curtain Protect human body sensing

The mode of human-machine collaboration has been around since its inception in industry. In the mechanical stamping industry, due to the lack of effective safety measures in the early stages, frequent industrial safety accidents occurred during human-machine collaboration, resulting in workers losing their fingers, arms, and lives. In 1952, the first safety grating in industrial history was born, which gradually provided personal safety protection for operators in the field of human-machine cooperation in industrial production. But the Industrial Revolution in China started relatively late. At first, people did not attach enough importance to industrial safety. In addition, the early main safety Gratings came from imports, which were expensive. Many stamping machinery and equipment did not have any effective safety protection mechanisms, resulting in frequent dangerous accidents. Until the early 1990s, domestic brands of domestically produced safety gratings began to emerge, driving the development of the domestic safety grating industry. Domestic safety gratings have been developed for 30 years, from the earliest low-level gratings to fully meeting international level four standards, and even showing a trend of gradually catching up with foreign brands.

Let technology serve us: improve security and convenience

You should know that we live in a world full of technological innovation, aimed at making our lives easier. But safety is crucial in places where machines move at high speeds, such as factories or warehouses. This is where safety systems such as safety light curtains and Safety Relays come into play, providing solid protection for personnel working around these powerful machines. Let's take a closer look at how these security devices work independently and collaboratively to create a truly safe workplace.

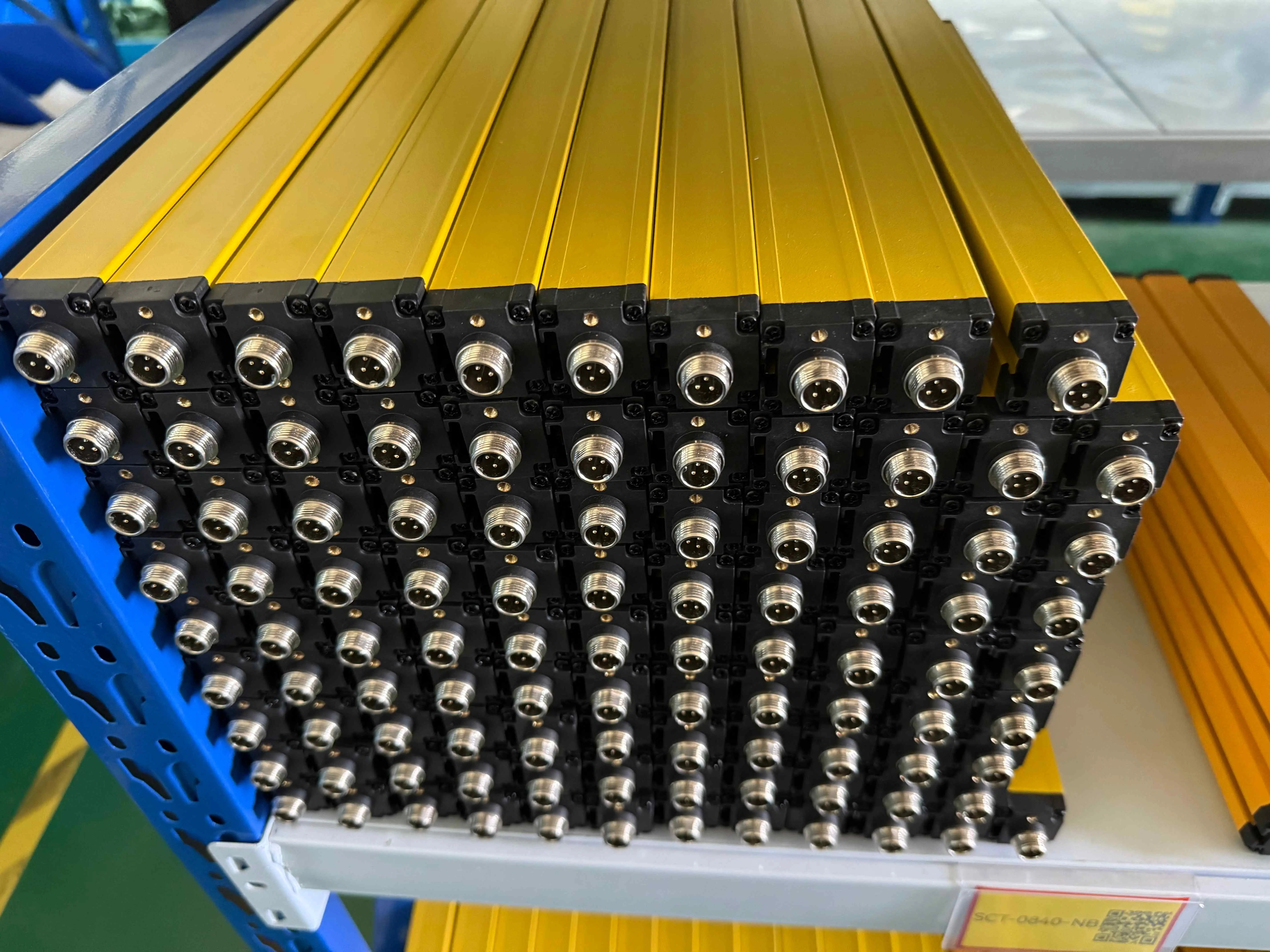

Safety light curtain

So, let's talk about safety light curtains! Simply put, these clever devices use light beams to create an invisible barrier. They are composed of rows of photoelectric sensors, usually installed in frames around hazardous areas. The coolest part? They can detect whether people or objects have entered designated areas. This means that they are like a non-contact safety net, and once the beam of light is blocked by anything, the machine will stop. These are some quick responses! In places where machines are constantly moving, such as assembly lines or robot workstations, this feature can make the world different.

The safety light curtain has a wide range of applications; They can prevent entry into hazardous areas, eliminate blind spots, and clearly delineate work areas within the factory to ensure the safety of workers. By creating these invisible boundaries, they help ensure that operators do not accidentally enter hazardous areas. They can be considered as important monitoring tools to ensure everyone's safety.

Even better, the safety light curtain can be customized to meet specific needs. Whether it is large-scale detection or precise positioning monitoring, they can perfectly adapt to different environments and have extremely wide applications.

Safety relay

Now, let's change the topic and talk about safety relays. These 'little champions' are the backbone of electrical protection in industrial environments. Their job is to ensure the safe operation of machines and effectively manage signals in circuits. Simply put, safety relays decode these signals and determine when to turn on or off the circuit based on emergency safety protocols. This means that if there is a problem, they can immediately stop potentially dangerous machines. Very cool, right?

You can consider the safety relay as the control center of the entire operation. They constantly monitor the current and are ready to take action in case of abnormal situations such as short circuits or overloads. They play a crucial role in detecting errors and preventing machines from accidentally starting or shutting down. In terms of industrial safety, safety relays are a crucial link.

Safety relays also have a dual function: they keep the equipment running smoothly, but also stop running in case of problems, ensuring the safety of everyone. They are an important component of any electronic security toolkit as they are fully integrated with motors, sensors, and controllers.

The powerful functions of safety gratings and safety relays

The bottom line is this: safety gratings and relays are more powerful when combined into a complete safety system. They work together to elevate workplace safety to a whole new level while ensuring the safety of both personnel and machines.

The safety relay is like a guard dog for the electrical part of a machine, providing a solid first line of defense against unauthorized movement, while the safety grating continuously monitors the physical environment and uses its sensors to capture any unexpected movements.

When the light barrier detects motion and immediately communicates with the safety relay, the magic of the grating becomes apparent. The safety relay says, "Hey, we have a problem!" This fast communication instructs the relay to shut down the machine to prevent any accidents - in my opinion, this is a great fail safe mechanism. With this double-layer protection, the risk of failure is greatly reduced. In busy production environments, this peace of mind is priceless.

But this is not just to avoid danger; If these systems are set up correctly, they can actually improve operational efficiency! The rapid threat detection function can reduce downtime and ensure smooth production. In addition, they also save time and effort from manual monitoring, allowing people to focus on more important tasks. All of this is to make the process more efficient and intuitive.

The adoption of safety gratings and relays is also fully in line with the goals of Industry 4.0, which are automation and smarter solutions. We are working hard to create factories that prioritize not only safety but also productivity. The key to this transformation is real-time threat management, predictive maintenance, and creating a security culture that involves everyone

summary

In short, the integration of technologies such as safety light curtains and safety relays truly reflects our commitment to intelligent and humanized safety upgrades. They represent an important step towards interactive security solutions that not only protect our machines, but more importantly, protect our employees. It's like integrating security and convenience into a seamless solution.

With the changes and developments in the industry, we prioritize safety and constantly push the boundaries of technology. We envision a future where risks are minimized, workers are safe, and operations proceed smoothly. Welcome to a new era of security solutions, where we tirelessly strive to protect and improve our workplace!