The importance of grating in the new era

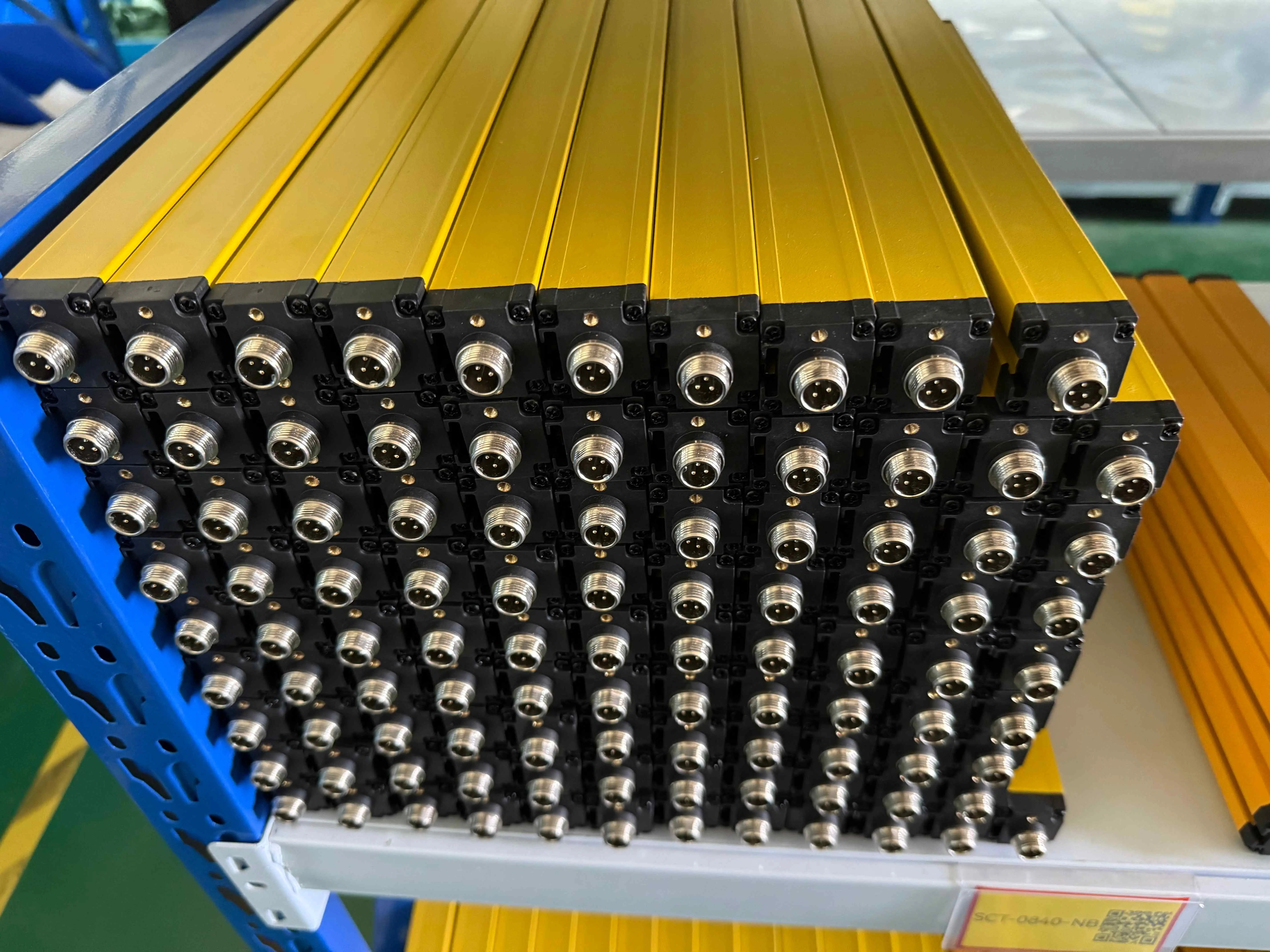

**Lighting up safety: the role of light curtains in modern manufacturing**

In the complexities of modern manufacturing, safety is no longer just a buzzword, but an essential element that drives operational efficiency and well-being. As industry continues to evolve, automation and sophistication increase, the importance of safety measures has become paramount. Among these measures, Safety light curtains have become a key tool to bridge the gap between efficiency and protection. In this blog post, we will explore how these advanced light curtains are redefining safety in today's manufacturing industry.

### Learn about safety light curtains

Safety light curtains are optoelectronic devices designed to protect personnel from injuries associated with the operation of machinery. They form an invisible barrier around hazardous equipment, ensuring that if an object or person crosses the beam, the machine stops immediately. This important safety feature prevents accidents and injuries common in high-speed manufacturing environments.

### The role of light grid in safety light curtain

Light Barrier technology is the cornerstone of safety light curtain design and functionality. Essentially, the term “light barrier” refers to the ability of these light curtains to split light into multiple beams. This segmentation enables precise detection and provides greater resolution when monitoring for obstacles. The more complex the light barrier, the more detailed data collected on potential interference, making today’s light curtains some of the most sophisticated devices in industrial safety.

### The importance of Grating in the new era

As we enter a new era in manufacturing characterized by unprecedented technological development and automation, the importance of light grids in safety light curtains becomes increasingly apparent.

#### 1. **Enhanced Precision and Accuracy**

Thanks to improved light grid technology, safety light curtains are able to detect even the slightest intrusion within a protective barrier. This level of accuracy is critical in industries such as automotive or electronics manufacturing, where even the slightest miscalculation can result in significant loss or damage. High-resolution light grids ensure that every object, no matter how large or small, is effectively protected, maximizing safety and productivity.

#### 2. **Improve adaptability**

Modern light curtains are highly adaptable thanks to advanced light grid systems, allowing manufacturers to tailor safety measures to specific needs. Whether the machine is used for heavy-duty operations or complex assembly lines, the customizable nature of the light grid ensures that the light curtain can effectively protect in a variety of scenarios.

#### 3. **Easy to integrate**

Modern safety protocols require tools that integrate seamlessly with existing systems without causing major disruption or requiring extensive retrofits. The flexibility offered by precision light grids enables safety light curtains to be easily installed into existing equipment. This reduces downtime associated with installing new safety systems while increasing worker safety without sacrificing production time.

#### 4. **Support Automation and Robotics**

Automation and robotics are at the forefront of the new era of manufacturing. Safety light curtains equipped with advanced light grid technology play a vital role in ensuring these automated processes run smoothly and safely. Capable of quickly identifying and responding to any irregularities along the path, these light grids provide indispensable support in maintaining the delicate balance between human-machine interaction and automated operations.

### Bridging the gap between efficiency and safety

Modern manufacturing strives for optimal productivity, but safety must not be sacrificed. Safety light curtains are a perfect example of how effective technology can bridge this gap. With advances in light curtain technology, these tools not only ensure safety is paramount, but also optimize operational efficiency by minimizing incidents and downtime.

The future development trajectory of safety light curtains

Looking ahead, the future looks bright for safety light curtains, driven by technological advances and rising safety standards. As industries become more complex and demanding, the need for sophisticated safety measures grows. Light curtain technology will continue to evolve, offering finer resolution, faster response times and greater integration capabilities.

### in conclusion

In summary, safety light curtains based on advanced light grid technology are a key element of safety in modern manufacturing. These safety devices combine precision, adaptability, integration and automation support, providing unparalleled advantages. As manufacturers continue to innovate, the role of safety light curtains will always be crucial, ensuring that the pursuit of efficiency will never overshadow the importance of protecting human life.

As technology continues to advance, we must also prioritize exploring and implementing advanced safety measures to reflect the importance of human capital in every aspect of manufacturing. Safety light curtains, with their superior grating technology, are a model for achieving this balance, opening up a safe future path for all industries.