The Importance Of Laser Protection For Bending Machines

# Enhancing Safety and Precision: The Role of Laser Protection Devices for Bending Machines

As modern manufacturing processes increasingly emphasize efficiency, precision, and safety, the integration of advanced technologies into production equipment has become paramount. Bending machines, integral to metal forming operations, are no exception. The advent of laser protection devices for bending machines exemplifies how cutting-edge technologies can simultaneously safeguard machinery operators and ensure the high precision requisite in contemporary manufacturing environments. This blog will elucidate the function and accuracy of laser protection devices in the context of bending machines.

## The Importance of Bending Machine Protection

Bending operations involve the deformation of metal workpieces to form desired shapes and angles, typically through the application of substantial force. The precise nature of such operations presents several safety hazards, such as potential finger or hand injuries arising from inadvertent human-machine interactions. Additionally, intricate bends and angles necessitate a very high degree of accuracy, further complicating the process. To mitigate these risks and enhance operational efficiency, protective measures must be implemented.

## Laser Protection Devices: An Overview

A laser protection device, specifically designed for bending machines, employs laser technology to create a safety zone around the tool and workpiece. These devices use laser beams to detect any obstruction or intrusion into the designated safe area. When an obstruction is detected, the machine either slows down or stops automatically, thus preventing any potential injury or machine damage. The implementation of such devices is not only crucial for operator safety but also essential for maintaining the precision of the bending process.

## Functionality of Laser Protection Devices

### Safety Mechanism

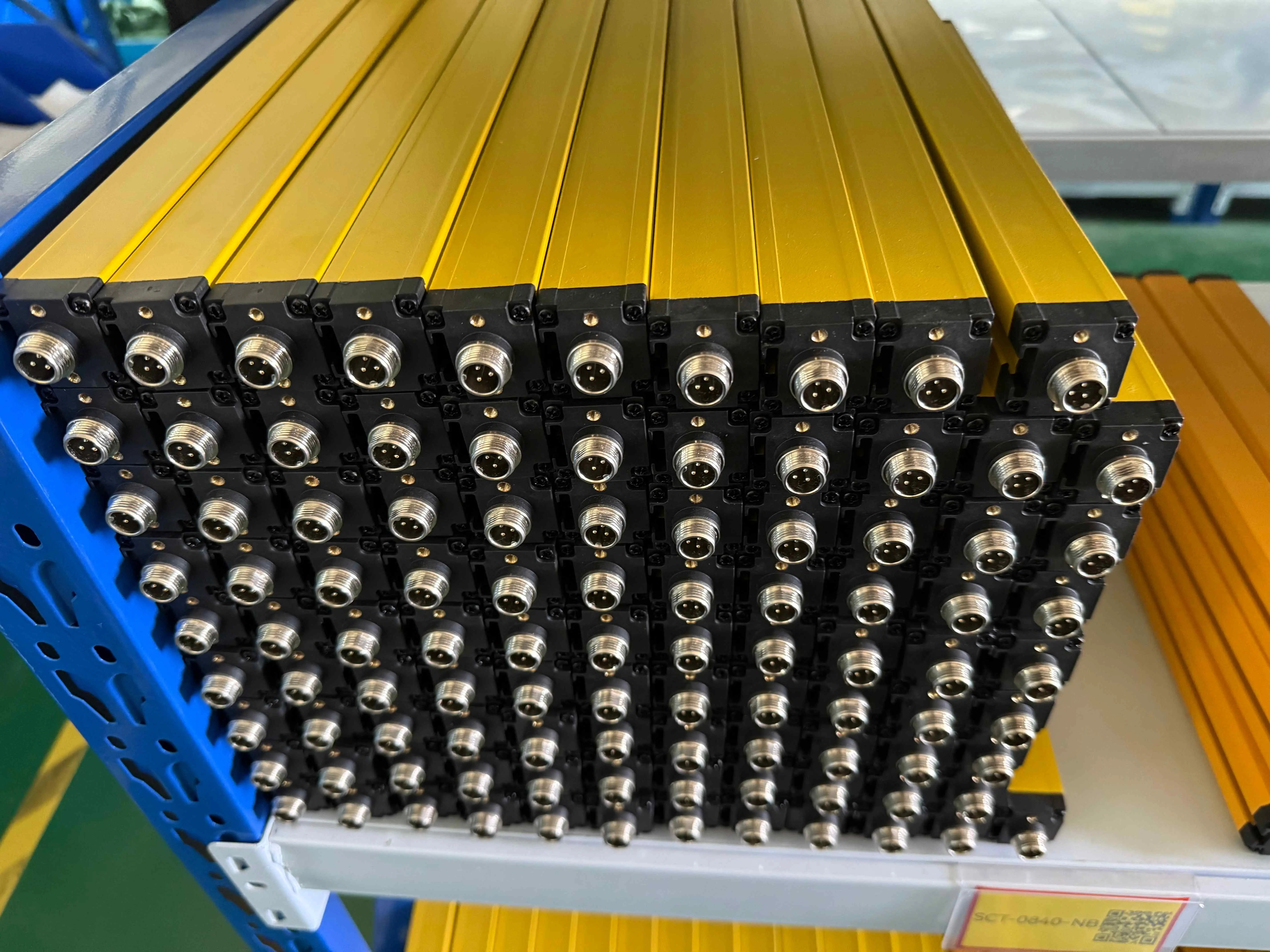

The primary function of the laser protection device is to act as an invisible shield around the moving parts of the bending machine. The system typically comprises multiple laser emitters and receivers arranged to create a grid or curtain of laser beams. These beams form a defined area around the critical zones of the machine, such as the bending tool and workpiece. As soon as an object breaks any of the laser beams, the system triggers the machine's safety control, halting the operation instantly.

Modern laser protection devices are equipped with advanced sensors and software, enabling them to distinguish between the necessary components of the machining process and unwanted intrusions. This discrimination capability minimizes false triggers, ensuring that the production workflow is not unduly interrupted.

### Enhancing Precision and Productivity

In addition to providing safety, laser protection devices contribute significantly to the precision of bending operations. The accuracy of the machine's actions is crucial, as even slight deviations can result in sub-standard products, leading to material wastage and increased production costs.

Laser systems enable real-time monitoring and calibration of the bending process. These devices can track and measure the position of the workpiece and tool with micro-level precision, ensuring the bending operation adheres to the predefined parameters. Some advanced systems also offer the ability to adjust the bending angle dynamically, accommodating any detected inconsistencies, thus maintaining the exactness of bends.

## Accuracy of Laser Protection Systems

### High-Resolution Sensing

Laser protection devices operate with a high degree of accuracy due to their advanced sensing capabilities. They employ high-resolution laser beams, capable of detecting minute deviations in the positioning of the workpiece. This precision is critical in applications requiring consistent and repeatable results.

### Real-Time Adjustments

The real-time nature of laser protection systems allows for immediate adjustments during the bending process. Sophisticated software algorithms analyze data continuously, enabling the system to recalibrate the machine’s movements on-the-fly. This functionality assures that each bend conforms precisely to the specified dimensions, enhancing the overall accuracy of the operation.

### Fault Detection and Diagnostics

Laser protection devices can also identify faults within the bending process. By continuously monitoring the machine’s performance, they can detect misalignments, tool wear, or other anomalies that might affect the quality of the bends. Early detection of such issues permits timely maintenance and adjustments, ensuring uninterrupted production and extending the life of the machine.

## Conclusion

The integration of laser protection devices into bending machines represents a significant advancement in metal forming technology. These devices not only enhance the safety of operators by creating an intuitive and responsive protective barrier but also contribute greatly to the precision and productivity of bending operations. Their ability to perform real-time monitoring and adjustments, coupled with high-resolution sensing capabilities, ensures that even the most demanding bending tasks are performed with unparalleled accuracy. As industrial processes continue to evolve, the adoption of such innovative technologies will undoubtedly become increasingly essential, driving efficiency and safety in manufacturing environments.

In summary, laser protection devices for bending machines epitomize the synergy of safety and precision, embodying the future of intelligent manufacturing solutions.