The Importance of Safety Gratings for Factory Operations

### Why safety light grids and Safety light curtains are vital to factories

Let’s be honest, safety is of paramount importance in today’s factories. Everyone is working hard to ensure everything runs smoothly while protecting the team and the equipment. As technology continues to advance, there are now some very clever safety solutions that can really meet the needs of manufacturing spaces. Among them, safety Gratings and safety light curtains are essential components that play their respective roles in ensuring the safe operation of the factory.

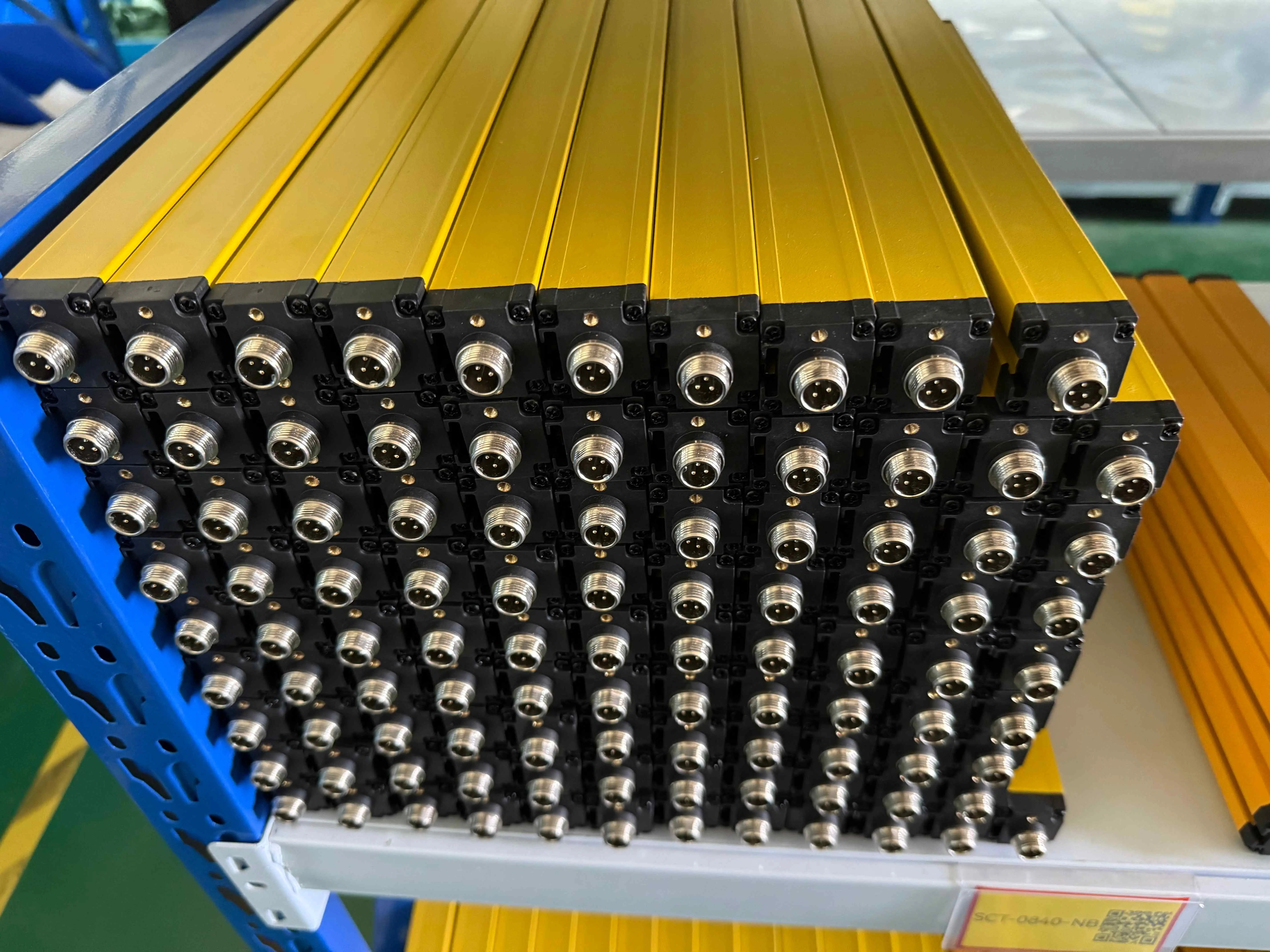

#### What is a safety light curtain?

Do you know the safety gratings that are commonly seen in industrial areas? They are durable, strong, and can create stable platforms or divide spaces, especially where items need to be isolated from the ground or away from dangerous areas. They are designed to prevent slips, trips, and falls - annoying accidents that often occur on uneven or slippery surfaces. You can find safety gratings made of steel, aluminum, or fiberglass, depending on the specific needs of your plant, such as chemical resistance or anti-slip.

Installing safety grilles in your plant not only prevents accidents, but also helps delineate safe areas for heavy machinery. In addition, safety grilles greatly simplify maintenance by allowing workers to safely access equipment. This allows team members to perform necessary inspections and repairs without having to worry about a complex plant setup.

####The role of safety light curtains

Now, let's talk about safety light curtains - while safety light grids control physical movement, light curtains provide an invisible barrier. They use infrared beams to detect if someone is too close to a danger zone. These devices are important, especially in automated factories, where machines may move quickly or working near moving machinery can be dangerous.

Here’s how they work: Safety light curtains emit an invisible beam of light that, if blocked, instructs the machine to stop or switch to a safe mode. This fast response is critical to preventing injuries from accidental entry into the machine’s operating area, such as moving parts on a stamping press or robotic arm.

#### Ensuring safety together

While safety light grids and light curtains are effective on their own, they are even more effective when used together in a factory environment. Combining physical and electronic safety measures creates a work environment where efficiency and safety coexist rather than conflict with each other. This combination can significantly reduce the risks associated with machinery and work processes.

For example, you can enclose the area around heavy machinery with a solid safety fence to restrict access, while installing light curtains for additional protection. This not only helps maintain smooth operations, but also avoids unnecessary downtime or safety issues. With both systems installed, the plant can truly focus on operations while still complying with safety regulations.

The benefits of these safety measures

There are many benefits to installing safety light grids and light curtains in your factory. Firstly, they help reduce workplace accidents, which means less downtime and increased productivity. Workplace accidents can hit a company hard – not only in terms of lost work time, but also in terms of legal disputes and claims. Therefore, investing in safety is not only a smart move, it’s a necessity.

Beyond that, having a strong security system demonstrates that you take your employees’ well-being seriously, which goes a long way toward building trust and professionalism. When employees feel safe in their environment, they’re happier and more engaged because they know their safety is a top priority.

Finally, factories that invest in these safety measures are often able to enhance their brand reputation and global competitiveness. It becomes easier to obtain safety certifications and comply with standards, helping them stand out as leaders in responsible, modern manufacturing practices.

Summarize

Therefore, it is critical for today's factories to install tightly integrated safety systems such as safety light grids and light curtains. They not only ensure safety, but also promote an orderly, efficient and effective workplace. As factories integrate and evolve with new technologies, taking strong safety measures will be key to sustainable development. Factories that put safety first will not only protect their employees, but also lay the foundation for their own long-term success. With safety in mind, the manufacturing industry can continue to move forward while ensuring the well-being of employees and meeting market demands.