The use of safety light curtains and safety relays can greatly improve personnel safety

## Enhance workplace safety with safety Light Barriers and safety relays

In modern industrial environments, worker safety is of paramount importance. Ensuring that machines and automated processes meet safety standards is essential to preventing accidents and injuries. Safety light barriers and safety relays are two important components in achieving this goal. This blog post aims to take a deeper look at these two important safety measures, exploring their individual functions and the synergies that occur when they are used together.

### Learn about safety light barriers

#### What is a Safety light curtain?

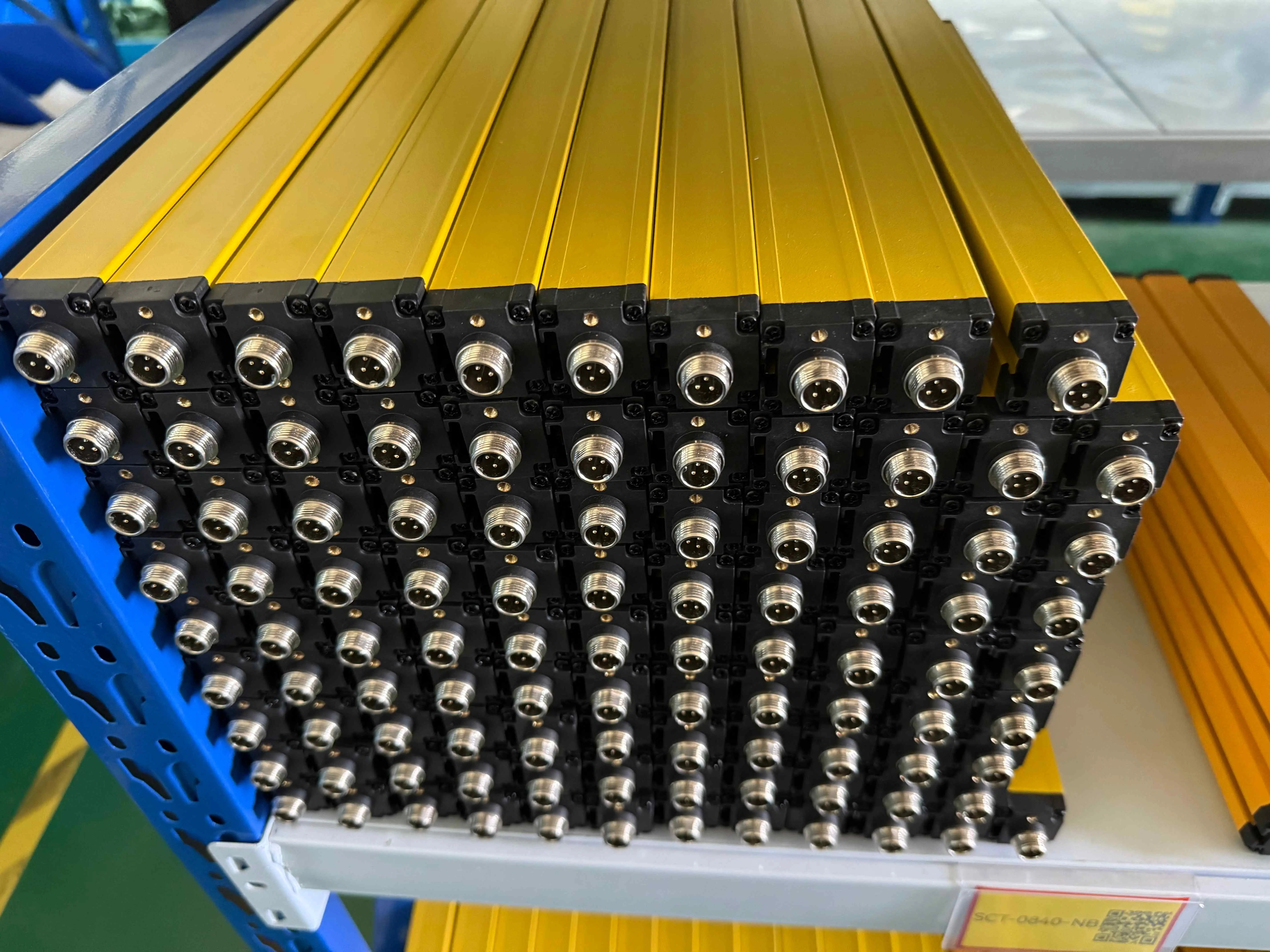

A safety light grid, also known as a safety light curtain, is an optoelectronic protective device used to protect hazardous areas. It consists of multiple light beams arranged in parallel to form a grid-like pattern. These beams are emitted by a transmitter and received by a receiver located on the other side. When an object such as a human hand or other body part blocks one or more of the beams, the device detects the interference and sends a signal to stop the machine, thereby preventing a potential accident.

#### Main features of safety light curtains

1. **Non-Intrusive Security Measures**: Security light barriers are non-intrusive security measures, meaning they do not require a physical barrier. This feature allows for free movement and access while maintaining a high level of security.

2. **High resolution**: These devices can detect even the smallest disturbance, ensuring that even the smallest body parts, such as fingers, can trigger a safety response.

3. **Adjustable range and resolution**: Safety light grids have adjustable resolution and detection range, suitable for a variety of applications from protecting small machinery to large industrial robots.

4. **Easy to integrate**: Safety light curtains can be easily integrated into existing systems without major modifications and can be seamlessly integrated into different working environments.

### The role of safety relays

#### What is a safety relay?

Safety relays are a special type of relay used to ensure the reliable operation of safety-related components in industrial control systems. They are responsible for monitoring signals from safety devices such as emergency stop buttons, light curtains, and other safety sensors. Once an abnormal or dangerous situation is detected, the safety relay immediately signals the connected machine to enter a safe state, such as an emergency stop.

#### Main features of safety relays

1. **High reliability**: Safety relays are designed to meet strict safety standards and have high reliability. They are designed to ensure that the safety system can respond accurately at critical moments.

2. **Redundancy and Fault Detection**: Many safety relays contain redundant circuits and fault detection mechanisms. This redundancy ensures that even if one circuit fails, the safety relay can still keep the system in a safe state.

3. **Versatility**: Safety relays can handle a variety of inputs and outputs, making them suitable for different types of safety equipment and industrial applications.

4. **Diagnostic Features**: These relays usually come with built-in diagnostic features that allow for continuous monitoring and maintenance to ensure that the safety system remains operational.

### Synergy between safety light curtains and safety relays

#### Working together to improve worker safety

While safety light barriers and safety relays are very effective when used individually, their combined use can significantly improve workplace safety. Here's how they work together:

1. **Immediate response**: When the safety light curtain detects a disturbance (such as a worker entering a hazardous area), it sends a signal to the safety relay. The safety relay then processes the signal and triggers an emergency stop of the machine, ensuring that the dangerous operation is stopped quickly.

2. **Integration and communication**: Safety relays act as a communication hub between various safety devices, including light barriers. This centralized monitoring mechanism ensures coordinated safety measures between the various components of the safety system.

3. **Full safety coverage**: Using safety relays and safety light curtains ensures that multiple safety mechanisms are in place. The light curtains provide non-intrusive perimeter protection, while the relays are able to effectively process and execute safety protocols, thereby fully covering potential hazards.

4. **Compliant system**: Both components comply with international safety standards. When used together, they not only improve the safety of the working environment, but also ensure that industrial operations meet regulatory requirements.

#### Practical application of combination

**Automation & Robotics**: In automated production lines and robotics, safety light curtains ensure that operators are protected from robotic arms and autonomous machinery. Safety relays further ensure that the system immediately enters a safe state when an intrusion is detected.

**Presses and Cutters**: In environments where presses or cutters are used, safety light barriers protect the operator's hands and arms. Safety relays ensure that the machine stops immediately if any anomalies are detected to prevent injuries.

**Assembly Line**: On assembly lines where workers frequently interact with machines, light curtains can monitor safety zones, while safety relays can manage safety interlocks and emergency stops to ensure a safe working environment.

### in conclusion

In summary, safety light curtains and safety relays are indispensable in modern industrial safety systems. Each component has unique features and benefits that contribute to a safer working environment. Together, they form a powerful and comprehensive safety solution that significantly enhances worker protection. As industry continues to develop and automation becomes more popular, the combined use of safety light curtains and safety relays will continue to be a key part of industrial safety protocols, ensuring that machines operate safely and reliably, and most importantly, protecting the safety of workers.