Unlocking Safety: The Power of Safety Light Curtains and Relays

**Putting technology to work for us: Improving safety and convenience**

You know, we live in a world full of technological innovations designed to make our lives easier. But in places like factories or warehouses where machines are moving at high speeds, safety is paramount. That’s where safety systems like Safety light curtains and safety relays come into play, providing solid protection for people working around these powerful machines. Let’s take a closer look at how these safety devices work independently and together to create a truly safe workplace.

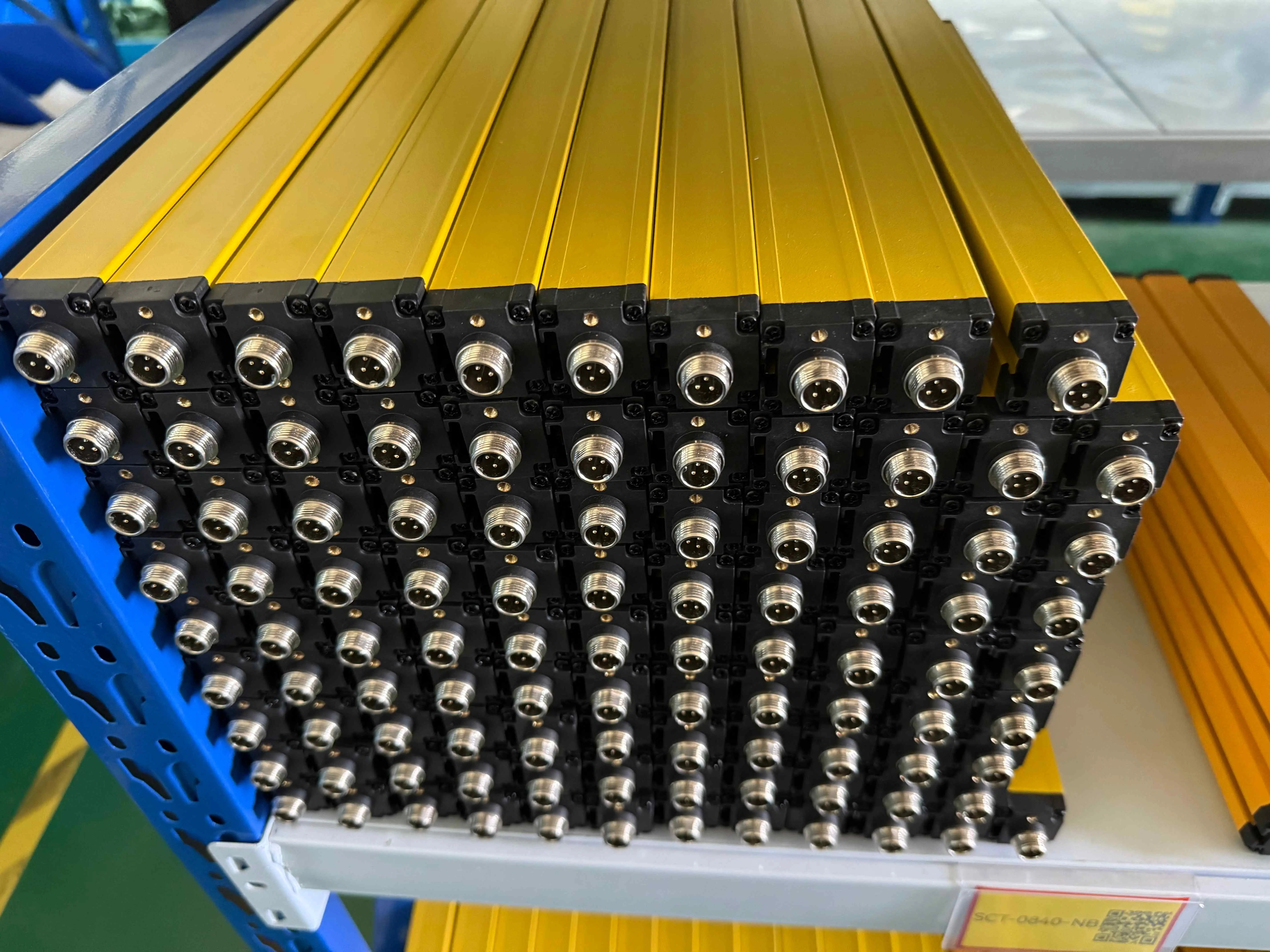

**Safety light curtain**

So, let's talk about safety light curtains! In simple terms, these clever devices use light beams to create a kind of invisible barrier. They consist of rows of photoelectric sensors, usually mounted in a frame around a danger zone. The coolest part? They can detect if a person or object has entered a designated area. This means they act like a contactless safety net, stopping the machine as soon as the beam is blocked by anything. That's some fast response! In places where machines are constantly moving, such as assembly lines or robotic workstations, this feature can make a world of difference.

Safety light curtains have a wide range of uses; they can block access to hazardous locations, eliminate blind spots, and clearly delineate operating areas within a factory, keeping workers safe. By creating these invisible boundaries, they help ensure that operators don’t accidentally stray into hazardous areas. They can be considered an important monitoring tool to keep everyone safe.

Even better, safety light curtains can be customized to meet specific needs. Whether it is large-scale detection or precise positioning monitoring, they can perfectly adapt to different environments and have extremely wide applications.

**Safety Relay**

Now, let’s switch gears and talk about safety relays. These “little champions” are the backbone of electrical protection in industrial environments. Their job is to ensure that machines operate safely and effectively manage the signals in the circuit. In simple terms, safety relays decode these signals and decide when to open or close the circuit based on emergency safety protocols. This means that if something goes wrong, they can immediately stop a potentially dangerous machine. Pretty cool, right?

You can think of safety relays as the control center of your entire operation. They constantly monitor the flow of electricity, ready to take action if something unusual occurs, such as a short circuit or overload. They play a vital role in catching errors, preventing machines from accidentally starting or shutting down. When it comes to industrial safety, safety relays are a vital link.

Safety relays also do double duty: They keep equipment running smoothly but also stop operations if something goes wrong, keeping everyone safe. They are an essential component in any electronic safety toolkit because they work comprehensively with motors, sensors, and controllers.

**Powerful functions of Safety Light Grids and safety relays**

The bottom line is this: Safety light barriers and relays are even more powerful when combined into a complete safety system. Working together, they take workplace safety to a whole new level, keeping people and machines safe at the same time.

Safety relays act like guard dogs for the electrical portion of the machine, providing a solid first line of defense against unauthorized manipulation, while safety light barriers constantly monitor the physical environment, using their sensors to catch any unexpected movement.

The magic of light barriers is revealed when they detect motion and immediately communicate to the safety relay, which says, "Hey, we have a problem!" This rapid communication instructs the relay to shut down the machine to prevent any accidents from happening - a pretty awesome fail-safe mechanism in my opinion. With this double layer of protection, the risk of failure is greatly reduced. In a busy production environment, this peace of mind is invaluable.

But it’s not just about avoiding danger; if these systems are set up correctly, they can actually improve operational efficiency! Rapid threat detection capabilities can reduce downtime and ensure smooth production. In addition, they save time and energy on manual monitoring, allowing people to focus on more important tasks. It’s all about making processes more efficient and intuitive.

The adoption of safety light barriers and relays also fits perfectly with the goals of Industry 4.0, which is all about automation and smarter solutions. We are working to create factories that prioritize not only safety but also productivity. The key to this transformation is real-time threat management, predictive maintenance, and creating a safety culture that involves everyone.

**Summarize**

In short, the integration of technologies such as safety light curtains and safety relays truly reflects our commitment to intelligent, user-friendly safety upgrades. They represent an important step towards interactive safety solutions that not only protect our machines, but more importantly, our people. It's like safety and convenience merged into one seamless solution.

As the industry changes and evolves, we put safety first and continue to push the boundaries of technology. We envision a future where hazards are minimized, workers are safe, and operations run smoothly. Welcome to a new era of safety solutions, where we work tirelessly to protect and enhance our workplaces!